In a world where efficiency and quality reign supreme, organizations are constantly seeking ways to optimize their processes and deliver superior products or services. One approach that has gained prominence across various industries is lean six sigma Combining the principles of Lean and Six Sigma, this methodology offers a comprehensive toolkit for process improvement and performance enhancement. In this blog, we will delve into the core concepts of Lean Six Sigma, its principles, methodologies, and the transformative impact it can have on your business.

Understanding Lean Six Sigma

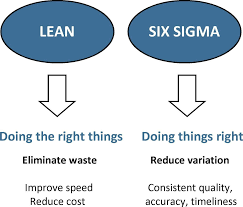

Lean Six Sigma is a hybrid methodology that marries two powerful philosophies: Lean, which focuses on reducing waste and improving flow, and Six Sigma, which emphasizes reducing defects and variations in processes. The synergy of these two approaches results in a holistic strategy for enhancing efficiency, quality, and customer satisfaction.

Key Principles of Lean Six Sigma

- Customer-Centric: Lean Six Sigma places the customer at the center of its initiatives. It aims to deliver products or services that align with customer needs and expectations.

- Data-Driven: Just like Six Sigma, data is the lifeblood of Lean Six Sigma. Data analysis is crucial for identifying issues, measuring performance, and making informed decisions.

- Waste Elimination: Lean principles drive the elimination of waste in processes. Waste is categorized into eight forms: defects, overproduction, waiting, non-utilized talent, transportation, inventory, motion, and extra processing (DOWNTIME).

- Continuous Improvement: A culture of continuous improvement is fostered, where teams work collectively to identify problems, implement solutions, and monitor progress.

- PDCA Cycle: Lean Six Sigma employs the Plan-Do-Check-Act (PDCA) cycle for problem-solving and continuous improvement. This iterative process ensures sustained progress.

The DMAIC and DMADV Methodologies

Lean Six Sigma projects typically follow two main methodologies:

- DMAIC (Define, Measure, Analyze, Improve, Control): DMAIC is used for improving existing processes. It begins by defining the problem, measuring current performance, analyzing data, making improvements, and establishing controls to sustain the improvements.

- DMADV (Define, Measure, Analyze, Design, Verify): DMADV is applied when designing new processes or products. It emphasizes designing processes that are inherently efficient and defect-free.

Benefits of Lean Six Sigma

- Improved Efficiency: Lean principles help organizations reduce waste, leading to streamlined processes and resource optimization.

- Enhanced Quality: Six Sigma methodologies minimize defects and variations, resulting in higher-quality products and services.

- Cost Reduction: Eliminating waste and reducing defects contribute to significant cost savings.

- Increased Customer Satisfaction: By aligning processes with customer needs, Lean Six Sigma improves customer satisfaction and loyalty.

- Competitive Advantage: Organizations that implement Lean Six Sigma gain a competitive edge through improved efficiency and quality.

Challenges in Implementing Lean Six Sigma

Implementing Lean Six Sigma successfully can be challenging due to resistance to change, the need for extensive training, and the time and resources required. However, the long-term benefits outweigh the initial hurdles.

Conclusion

Lean Six Sigma is a dynamic methodology that empowers organizations to excel in today’s competitive landscape. By combining the principles of Lean and Six Sigma, businesses can optimize processes, reduce waste, and deliver products and services that exceed customer expectations. Whether you’re in manufacturing, healthcare, or any other industry, Lean Six Sigma offers a structured approach to achieving operational excellence and sustainable growth. Embrace Lean Six Sigma, and embark on a journey to streamline success and drive lasting improvements.